Not All Carbon Fiber is the Same: Why Quality Matters in Wakesurfing

Share

When you hear the term "carbon fiber," it might be easy to think of it as a one-size-fits-all material. After all, carbon fiber is just carbon fiber, right? But in reality, not all carbon fiber is created equal. Just like any other material, the quality, manufacturing process, and design application can make a world of difference. At Smith Board Co, we believe that understanding these differences is crucial, not just for those of us in the engineering and design worlds, but for every rider looking to push the limits on the water.

The Spectrum of Carbon Fiber Quality

Carbon fiber is widely known for its high strength-to-weight ratio, but this doesn’t mean every carbon fiber product will perform the same way. The quality of carbon fiber can vary significantly based on several factors, including the type of carbon fibers used, the weave pattern, the resin or polymer matrix, and the manufacturing process.

- Type of Carbon Fibers:

- The most common types of carbon fibers are standard modulus, intermediate modulus, and high modulus. Each has a different level of stiffness and tensile strength. High modulus carbon fibers, for instance, offer the greatest stiffness but can be more brittle, while standard modulus fibers provide a good balance of strength, flexibility, and affordability.

- Weave Pattern:

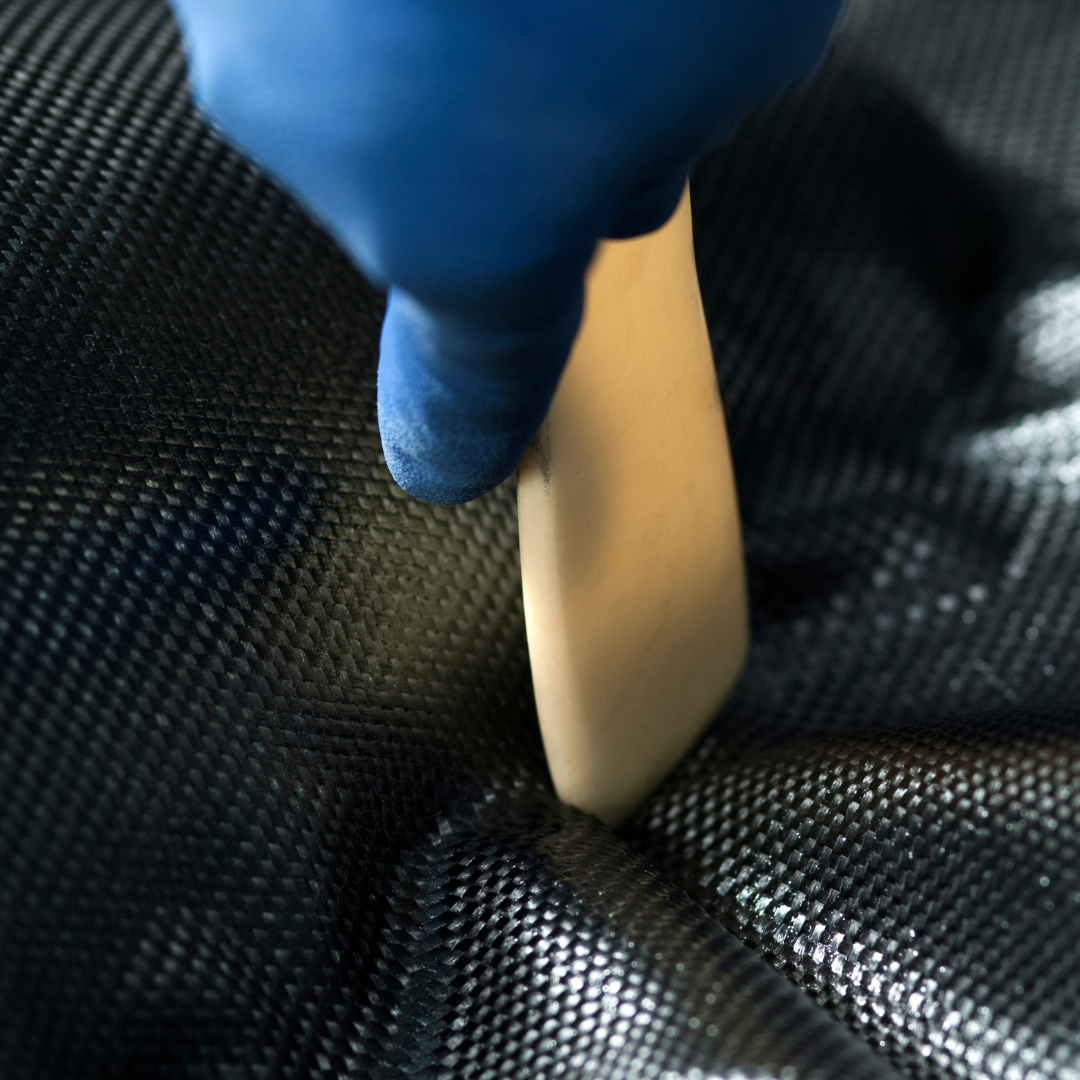

- The weave pattern of carbon fiber sheets can also affect performance. Whether it’s a plain weave, twill weave, or unidirectional fibers, each pattern influences the material’s strength, flexibility, and appearance. Twill weave, for instance, is often favored for its aesthetic appeal and slightly better drapeability around complex shapes, but plain weave can offer superior strength in certain applications.

- Resin Matrix:

- The resin or polymer that binds the carbon fibers together plays a critical role in determining the final composite's properties. The right combination of resin and carbon fiber can optimize strength, durability, and weight, but a subpar resin can lead to issues like delamination, where the layers of the composite start to separate under stress.

- Manufacturing Process:

- The process used to create the carbon fiber composite—whether it’s hand layup, vacuum infusion, or autoclave curing—also impacts the final product. Advanced techniques like autoclave curing, which uses high pressure and temperature to compact the layers of composite material, result in a stronger, more consistent product, but can be more costly and complex to produce.

Why Quality Carbon Fiber Matters in Wakesurfing

So, why should you, the rider, care about the differences in carbon fiber quality? The answer is simple: performance.

- Strength and Durability: High-quality carbon fiber means that your board can withstand the rigors of intense wakesurfing sessions without compromising on performance. Cheaper, lower-grade carbon fiber composites may not provide the same level of strength and could lead to premature failure or suboptimal performance on the water.

- Weight and Agility: Using top-tier carbon fiber allows us to create boards that are ultra-lightweight without sacrificing strength. This translates to faster speeds, quicker turns, and higher airs. When every ounce counts, you want a board that’s engineered with the best materials available.

- Consistency: The best carbon fiber composites are uniform in their properties, which means you get a consistent, reliable performance every time you step on the board. Inferior materials can lead to variability in the board’s behavior, making it harder to predict and control, especially in demanding conditions.

Our Commitment to Quality

At Smith Board Co, we don’t just use carbon fiber because it sounds good—we use it because it’s the best material for the job. But we’re not content with just using any carbon fiber. We’re committed to sourcing the highest-quality carbon fiber available and employing the most advanced manufacturing techniques to ensure that every board that leaves our shop meets the highest standards of performance and durability.

Our engineers painstakingly select the right type of carbon fiber, the optimal weave pattern, and the perfect resin system to create boards that aren’t just good—they’re exceptional. Whether it’s a board designed for speed, agility, or all-around performance, you can trust that the carbon fiber in your Smith Board Co board is of the highest caliber.