FEA: A Better Way to Design Wakesurf Boards

Share

What exactly happens to a car during a crash, or to the Golden Gate Bridge when it sways in the wind? What about when a rubber band snaps or you wear an indent into your favorite spot on the couch? When your laptop heats up your legs as you watch Netflix, or the handle on a pan gets hot enough to need an oven mitt? The last few of those aren’t too important, but knowing what happens in a car crash or when a bridge sways helps engineers build those things in a way that keeps us all safe. In engineering, you often want to know how something will behave before you build it. Especially if you're building it for other people to safely use like a bridge or a building.

A faster way to understand complex designs

For a long time, the process of understanding how something will behave under certain conditions was complex and painstaking. It took teams of engineers weeks, months, and sometimes years to come up with and solve all sorts of math problems. It took prototyping and breaking prototypes. Many times it actually took building a full-size model and putting it in different conditions to observe how it reacts. All of this took a lot of time, money, and hard work. For a majority of the 20th century this was the state of engineering, but in the late 1980’s scientists and engineers developed Finite Element Analysis or FEA and moved all that math and hard work into a computer. With the invention of FEA, engineers could now virtually model a design and simulate how it reacts under different conditions. They could simulate how it would bend and move when force is applied, or its temperature distribution when it’s subjected to heat. FEA is now used in almost every major industry to simulate physical interactions in a virtual environment. It’s used to simulate how all the pieces in a knee react when you walk or jump; to simulate manufacturing processes and manufacturing equipment. It’s used at SpaceX in rocket design, at Apple to build better phones, and at SmithBoardCo, we’re using it to understand wakesurfing so we can build higher performing wakesurf boards.

How FEA works

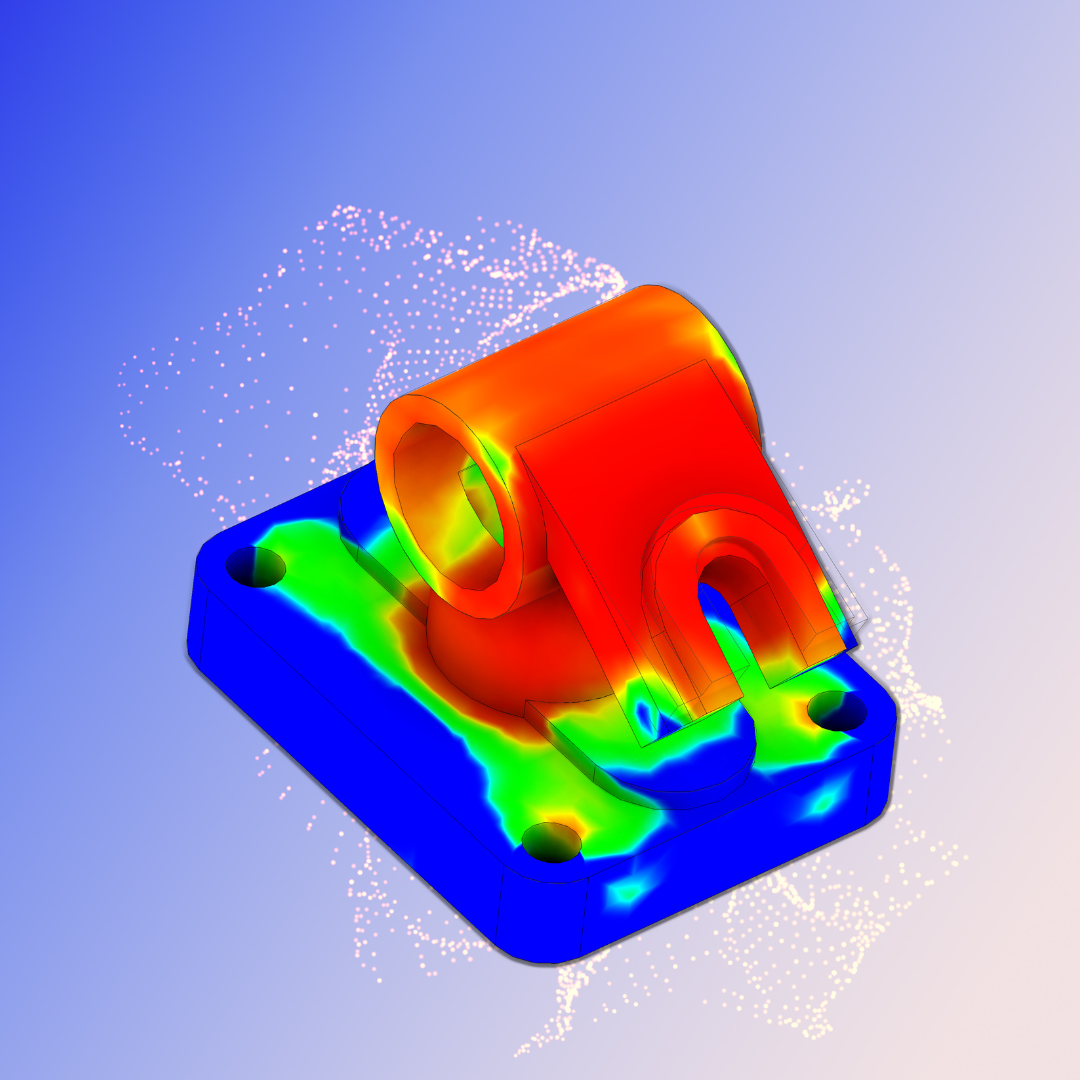

So what is FEA and how does it work? FEA is essentially a tool to predict how a model physically responds to different conditions. Whether that’s force inputs, heat input or vibrations, the goal of FEA is to understand what affect those inputs will have on your model. Those effects could be how the structure will flex and distort, how the materials fatigue under repeated stresses, or how the material transmits heat throughout its volume.

If you wanted to know how any of these things work, you would have to solve a physical equation governing how the physical process you're interested in affects the entire volume of the structure. Because the structure is big and usually has a complex shape, that equation becomes bigger and more complex as well. FEA simplifies this complex calculation by meshing the model, or breaking down that complex structure into thousands, millions, or billions of smaller, manageable pieces called finite elements. Each of these acts like a small, isolated piece of the puzzle, where the same equation that governs the complex whole is solved, but now over a much smaller and much simpler volume. These thousands to billions of smaller, simpler volumes that make up each finite element are defined by their own unique geometry (shape and size) and material properties (such as elasticity, density, and thermal conductivity). They are then connected to neighboring pieces by points at the corners or along the edges of connected elements.

As far as the equation that FEA solves for, it can be broken down, at a high level, to three parts.

- The inputs

- The physical properties of the finite elements substance

- The output

A common example of this is, for example one used to model what happens in a car crash, is the stress-strain equation. The stress-strain equation is used in FEA to model how the forces acting on a structure deform the different parts of that structure. In the case of a car crash, the inputs (1) are the forces that act on the car from whatever it crashes into (a wall or other car for example). The physical property of the structure's substance (2) is the stiffness of the materials (steel, plastic, etc) the car is made of. And the output (3) is the displacement (how much the hood of the car folds in on itself for example). The car example is made more complex by the fact that a car is made up of many different parts (the hood, the engine, etc) or structures (which can be broken down into their own set of finite elements), so you’re really tying together a collection of many individual FEA simulations.

But that’s a bit too much complexity for this explanation, so for now you just have to understand that the same equation that governs how an overall structure reacts to force inputs can be applied to each finite element in the structure to make solving that equation much much simpler. By solving the equation at the finite elements where the force is known (the pieces of the structure that are initially in contact with whatever is applying the force), you can see how that force displaces that finite element. That determines the force input to its neighboring finite element which can be used to determine its displacement and the force input to the next neighboring finite element and so on and so on until you’ve solved the equation for each finite element.

The local results from solving that equation in each of the finite elements can then be combined to understand the behavior of the entire structure. This global picture of how the entire structure responds to the force inputs can tell you things like what parts of the structure are weaker and more prone to break, or how much force the entire structure can take.

Using FEA to push wakesurf board performance

The math is all a bit complex for this and involves matrices and huge amounts of computation, but the gist of it is just solving essentially the same equation over and over, feeding the solution of one equation as the input to the next. It’s really a simple idea that has revolutionized how engineers design and understand the things they build. Here at SBC, we’re using FEA and tools like it to revolutionize not just the way boards are built and designed, but the way we all think about what's possible in the sport of wakesurfing.